The FlipScreen screen bucket is available in many different sizes and for all types of carriers, e.g. for excavators, wheel loaders, telescopic handlers, skid steer loaders or backhoe loaders.

Find out more in the data sheet.

The FlipScreen concept is simple and easy to use. The FlipScreen with the patented system picks up the material like a conventional bucket and then screens it in a smooth continuous 360 degree rotation – without shaking or vibrating. Finally, with a counter-rotation all the remaining oversize is ejected into the desired area.

The robustness and advantages of the FlipScreen screening bucket are unique. For example, it impresses with its waterproof spoon, which makes it possible to drive around the workstation without losing any load. Or the fact that the screen size can be changed in less than five minutes by a single person without tools. It can be used like a normal bucket. This also eliminates the need to change attachments for loading or unloading.

With the FlipScreen screening bucket you make your contribution to sustainability. You do not have to cart off the material on site and buy new goods. You can screen the existing material and produce the wished product. And you can recover top soil on site and put it right back in. At the same time you save fuel and time.

E.g. when taking out grass sods you can screen them and recover the top soil and pay only for the deposal of the grass roots.

#savesoil

Mesh sizes of 6, 13, 18, 25, 35, 50, 75, 150 and 300 mm are available. Which mesh suits best is determined by the material that you want to screen:

A mixing plate can be fitted for mixing concrete or feed.

Thanks to all the various meshes you can work up your material much further than with other screening buckets.

Tell us your type of carrier and what work you would like to do with the FlipScreen screen bucket – we will be happy to make you a suitable offer.

When screening sticky material it is recommended to use a brush kit, which removes clogged up material from the screen with each rotation.

In our well-equipped workshop, we will produce the right suspension for your FlipScreen screen bucket, whether it is for an excavator, wheel loader or skid steer loader. Do you have a sketch with the dimensions of the quick hitch coupler or a model name? That helps us heaps to serve you great.

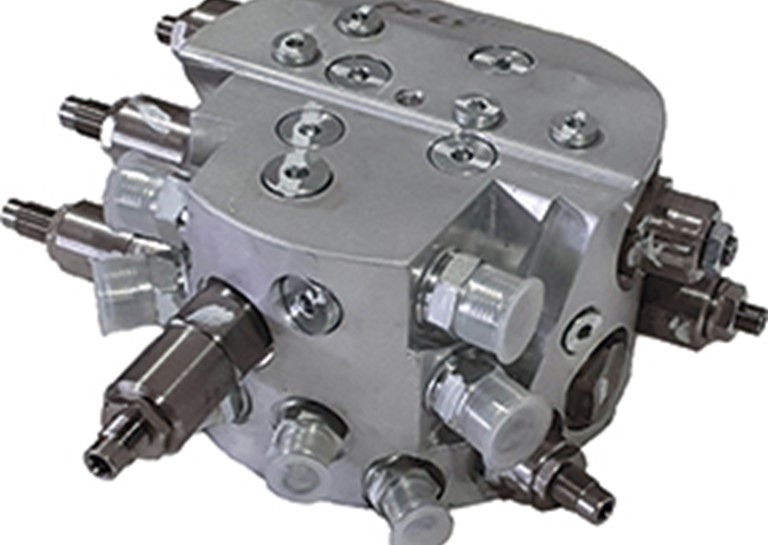

The unique smart valve allows the FlipScreen to be easily set up or interchanged between carriers without making any adjustments to the carrier's hydraulic installation.

With the largest screening surface in its class, it also offers more efficiency than the competition. The fact that the bucket can be used under water is also unique. Even concrete with reinforcement, demolition material as well as stones and gravel can be screened. Due to the many different screen sizes available, the material can be processed much further than usual.

If you would like to find out more about the versatile use of the FlipScreen screening bucket, you can find an article here, that was published in the magazine «Spektrum Bau».

See for yourself:

We look forward to your enquiry